Who We Are?

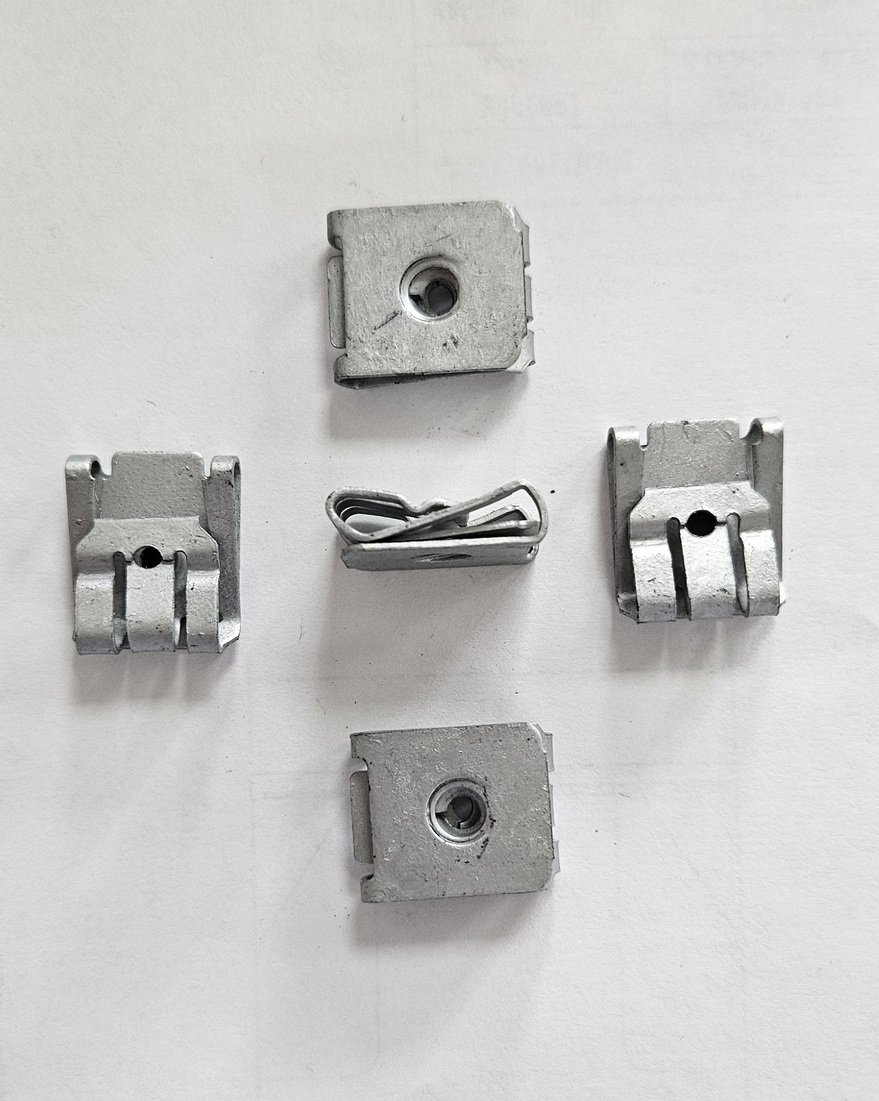

Dizayn Klips Ltd. Co. was established in 2008 and has specialized in the production of Clips, Electrical Terminals, and cable terminals in the automotive sector.

BCH Automotive, established in 2014, operates with a focus on the automotive industry. The company carries out sales and marketing activities in-house, while production processes are carried out through its group company Dizayn Klips.

Through this collaboration, BCH Automotive combines sectoral experience and engineering power to offer high value-added solutions to its customers.

Our Machine Park.

Our company carries out production activities for the automotive sector with a modern, technological, and highly efficient machine park. Our production infrastructure includes 6 Dongseo machines, 1 Bihler, 30, 45, and 85-ton capacity Howfit presses, 1 Bruderer press, 2 Lamination machines, 1 Gear cutting machine, and 1 Automated gear cutting machine.

Thanks to this powerful machine park, production is carried out in accordance with the high precision, quality, and continuity standards required by the automotive sector; providing reliable, competitive, and sustainable solutions to our customers.

Production-

Mold Shop

Our mold shop has a modern and powerful infrastructure for high-precision mold production for the automotive sector. In our production processes, 4 Wire EDM machines, 1 CNC machine, Grinding machine, High-speed drilling machine, and Lathe machines are actively used.

Thanks to our technological equipment and expert staff, we carry out mold manufacturing, maintenance, and revision work in accordance with quality, speed, and continuity principles, providing reliable solutions to our customers. -

Production

Our company carries out production activities for the automotive sector with a modern, technological, and highly efficient machine park. Our production infrastructure includes 6 Dongseo machines, 1 Bihler, 30, 45, and 85-ton capacity Howfit presses, 1 Bruderer press, 2 Lamination machines, 1 Gear cutting machine, and 1 Automated gear cutting machine.